Precautions for using weighing and packaging machines

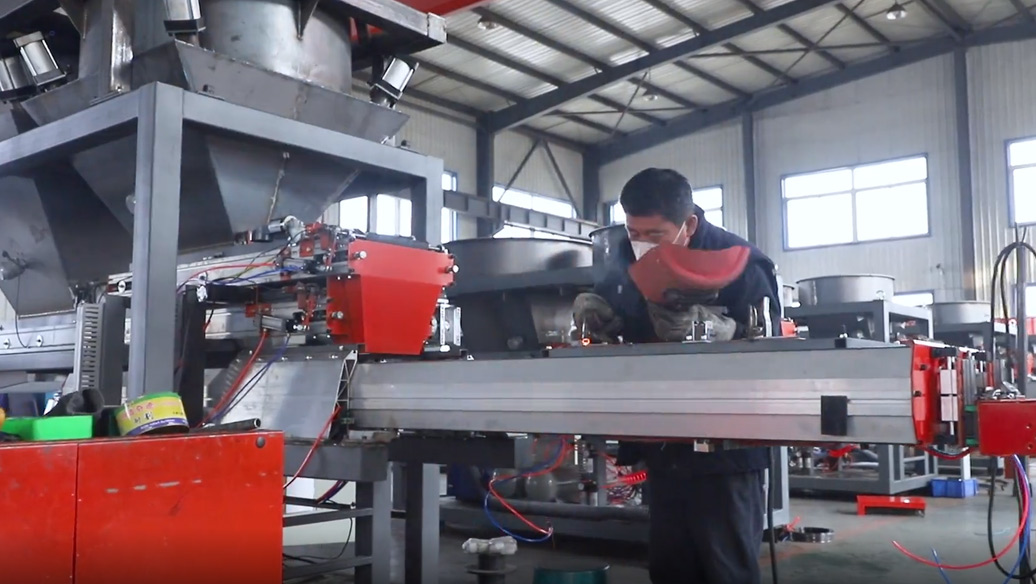

Release Date:2023.02.09 Page Views:50733Nowadays, the application scope of weighing and packaging machines is very wide. They are not only used domestically but also exported and sold in other foreign countries. Therefore, when we use it, we must make full preparations to ensure that the machine works better, reduces wear and tear, and extends its service life. Dreyer has listed the following four suggestions for everyone, hoping to be of help to users.

1. Strictly manage, control the packaging speed, and prohibit sudden packaging within a short period of time

Control the speed and efficiency strictly in accordance with the requirements of the manual to avoid chaos in a rush.

Second, strengthen the quality training of operators

It is necessary to conduct multi-faceted training for the operators, including internal and external training, as well as theoretical and practical training, so that the operators can generally reach the level of correcting weight errors.

Iii. Regularly calibrate the quantitative packaging controller and frequently perform point calibration

Regularly inspect the sensors of the weighing and packaging machine. Abnormal vibration or misoperation may cause misalignment, leading to weighing errors.

Fourth, strengthen quality monitoring

Quality inspection personnel are responsible for checking the packaging quality and urging the on-duty personnel to adjust the automatic packaging scale in a timely manner. Be responsible for the qualified rate of weighing, the rate of broken packages and the quality of palletizing. .

Since the emergence of human civilization, with the continuous development of The Times, human progress and the appearance of technology, it has been destined that commodities are increasingly closely related to people's lives, and these commodities play their unique charm in our lives. As a new type of packaging equipment, the weighing and packaging machine has its unique advantages in the fierce market competition. The wide range of its application determines its promising future.

Some precautions when using weighing and packaging machines:

1. Add a dust removal system

Evenly distribute the exhaust ducts around the scale of the weighing and packaging machine. There should be no dust around the weight sensing components, and the system should be cleaned regularly.

2. Strengthen the localization of accessories

With the continuous spread of the epidemic and the unstable situation in the United States, the import of many components has been affected. Therefore, we have taken the initiative to cooperate with domestic component manufacturers to achieve the localization of weighing and packaging machine components, reducing the impact of the epidemic and the international situation on the production of multiple enterprises. At the same time, we suggest that when replacing components, you should choose domestic components as much as possible to avoid affecting normal use.

3. Strengthen the maintenance and upkeep of weighing and packaging machines

Strengthen the maintenance of mechanical components in the system to keep them in good condition. Replace vulnerable parts in a timely and regular manner according to production needs. Such as knife edges, knife seats, balance weights, ball bearings, bearing bushings, pressure cylinders, support pins and solenoid valves, etc.

4. Replace the radiator of the drying system

The weighing and packaging machine is equipped with air ducts and water-cooled pipes. Try to minimize the temperature of the salt entering the warehouse. Wet salt is stored in the salt silo.

5. When using a stainless steel electronic packaging scale, it must not be overloaded. Pay attention to the humidity and the amount of smoke and dust in the operating environment. Clean up the debris below in time to avoid accumulation. The weighing sensor inside the packaging scale is very important. Avoid heavy objects from hitting it.