Common structural types of palletizing robots

Release Date:2023.02.16 Page Views:49921Palletizing robots can be classified into four common types based on their structure: Cartesian coordinate palletizing robots, full-joint structure palletizing robots, parallelogram structure palletizing robots, and linear horizontal multi-joint palletizing robots. These four types of palletizing robots are respectively used in different palletizing scenarios. Let's introduce them respectively below.

The Cartesian coordinate palletizing robot, also known as the truss palletizing robot or gantry palletizing robot, is based on the XYZ Cartesian coordinate system as its basic mathematical model and a single-axis mechanical arm driven by servo motors and stepper motors as its basic working unit. It can complete the arrival at any point in the XYZ three-dimensional coordinate system and follow a controllable motion trajectory.

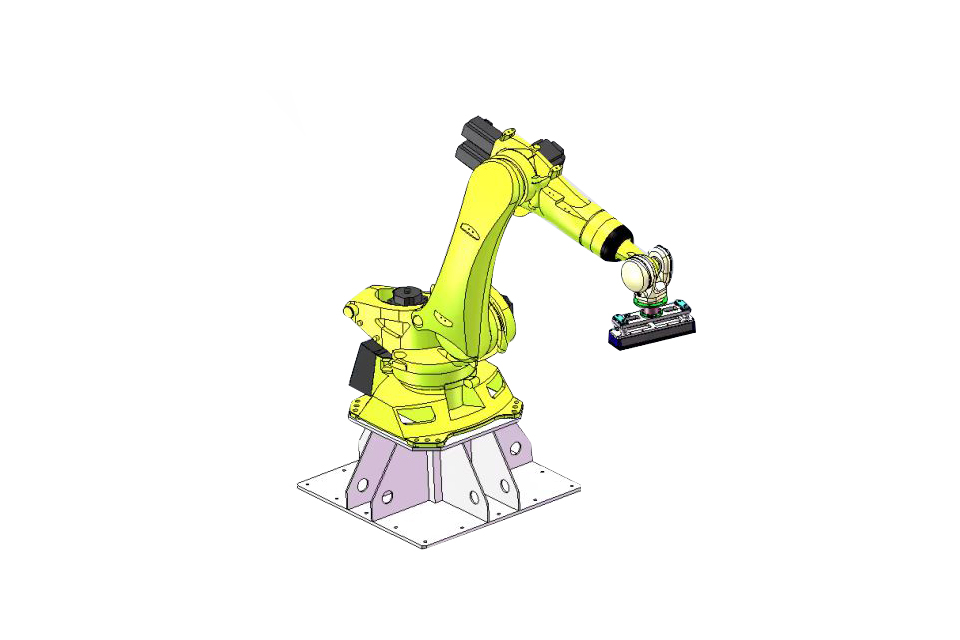

The full-joint structure palletizing robot has four degrees of freedom, namely four rotating joints, and is highly versatile. It is widely used in the palletizing of cartons, plastic boxes, bottles, bags, barrels, film-wrapped products and filled products. The structural design is simple, the movements are stable and reliable, and the palletizing process is completely automatic. No manual intervention is required during normal operation.

The paralleloquadrilateral architecture palletizing robot is magnified through two linear axes and a complex hinge structure. It not only has a large number of parts but also is difficult to install. Because it does not require algorithm support, most low-end palletizing robots take this architecture as their prototype.

The linear horizontal multi-joint palletizing robot has the same stability and high efficiency as the full-joint robot, the same cylindrical coordinate system as the parallelogram-structured palletizing robot, and the same low cost as the right-angle palletizing robot architecture.