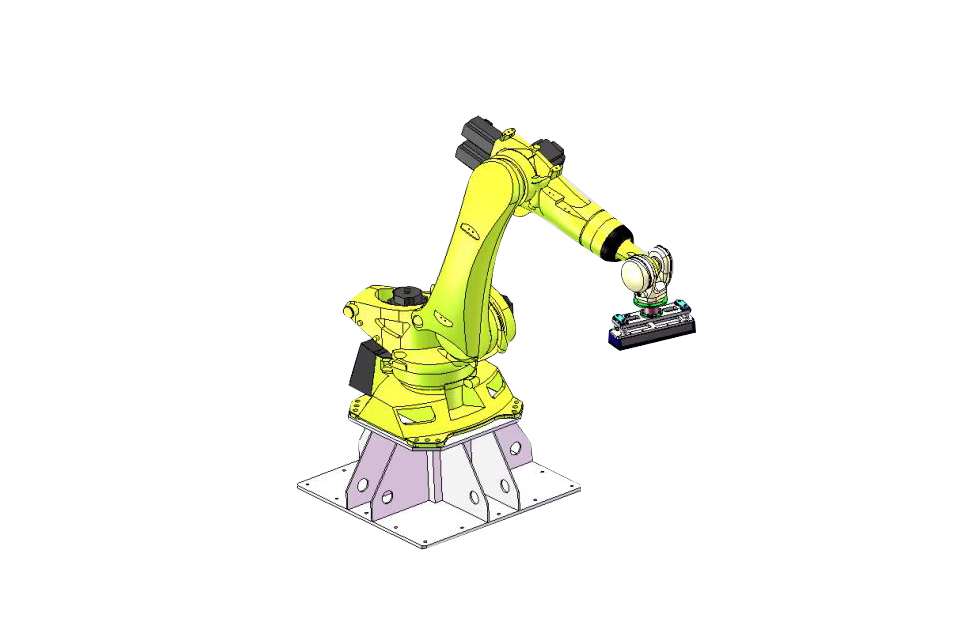

Safe operation of automatic palletizing robots

Release Date:2023.02.18 Page Views:49873When operating an automatic palletizing robot, safety must be given top priority. This is not only about the safety of the robot itself, but also the safety of the operator. To ensure safety and efficiency during the operation process.

First of all, before officially operating the palletizing machine, the operator must conduct a preliminary inspection of the equipment. The main points are to check whether the equipment can operate normally, whether all power lines are connected correctly, and of course, to check if there are any obstacles near the work site, as well as whether some mechanical parts are loose and other issues. All these need to be inspected carefully.

Secondly, after inspecting the palletizing machine and its surrounding working environment, check the oil tank. Under normal circumstances, as long as the palletizing robot is running every day, it needs to be refueled every day. If it is not refueled, it will not only cause abnormal or damaged cylinders, but in severe cases, it may also cause overall failure of the palletizing machine.

Although modern palletizing machines have high palletizing efficiency, if the operators do not pay attention to the arrangement of the packaged boxes, it will also affect the palletizing effect of the palletizing machine. Therefore, before officially starting the palletizing machine, it is essential to check whether the direction of the bags to be moved and palletized is consistent with the direction of the palletizing machine itself.

In case of any emergency during operation, it is essential to turn off the switch in time. Different areas of the palletizing robot have their own switches, such as an emergency off switch in the turning area and an emergency stop switch in the box entry area. Operators must be familiar with the locations of these switches so that they can make correct operations in time when encountering emergencies.

Previous Article:The specific operation steps of the rice bagging machine

Next Article:The importance of automatic palletizing machines in production