In what industries are palletizing machines mainly used?

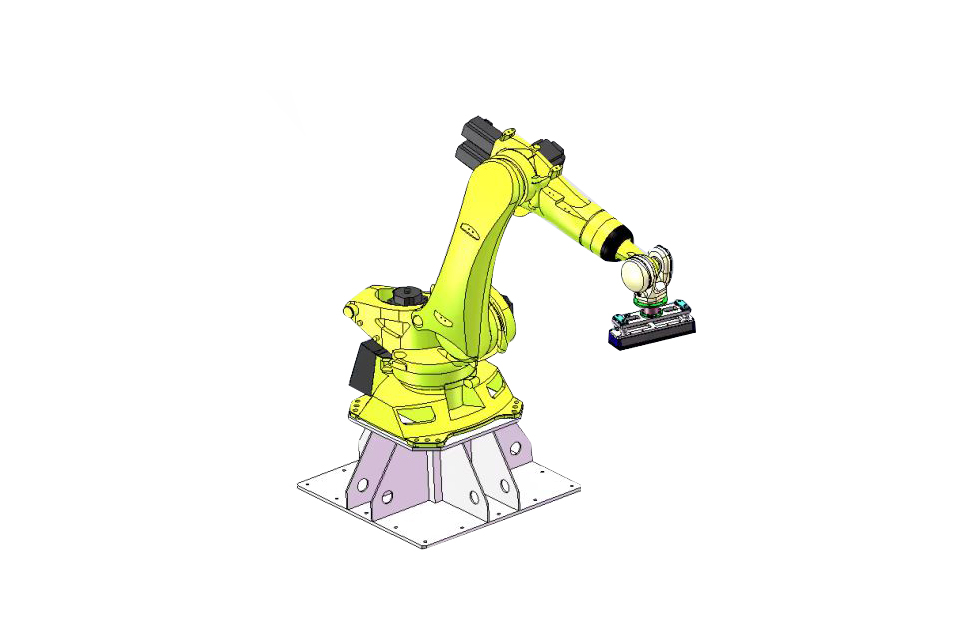

Release Date:2023.03.14 Page Views:52229In what industries are palletizing machines mainly used? In recent years, with the strong support of policies, the domestic intelligent equipment manufacturing industry has achieved considerable development. In the previous industrial production processes, not only was a large amount of manual labor required, but also there were often many product quality defects in the manufacturing process of enterprises. These defects seriously affected product quality. Therefore, the use of a large number of palletizing robots to replace manual labor has become particularly important.

After all, the production efficiency of a palletizing machine is several times that of traditional manual manufacturing. With the continuous application of palletizing machines, they have gradually replaced some traditional processing techniques. At present, in fact, many industries at home and abroad are already using palletizing machines in large quantities.

1. Automotive industry

In China, 50% of industrial robots are used in the automotive industry, among which over 50% are welding robots. In developed countries, automotive industrial robots account for more than 53% of the total number of robots. According to statistics, the major global automakers produce more than 10 robots per 10,000 vehicles annually. With the continuous development and improvement of robot technology, industrial robots are bound to promote the development of the automotive manufacturing industry. While China is shifting from manufacturing to manufacturing, it is necessary to improve processing methods, enhance product quality and increase the competitiveness of enterprises. All of this indicates that the development prospects of robots are huge.

2. Rubber and plastic industry

The plastic industry works closely together and is highly specialized: plastic production, processing and mechanical manufacturing are closely linked. Even in the future, this industry will become an important economic sector. Because plastic is almost everywhere: from the automotive and electronics industries to the consumer goods and food industries. Mechanical manufacturing plays a crucial role as a technological process for production and processing. Raw materials are processed into injection molding machines and tools to become innovative, fine and durable finished or semi-finished products - through automated solutions, the production process becomes more stable and reliable.

3. Application in the industrial products industry

As the palletizing machine can perform palletizing and boxing operations on various products, the accuracy of product boxing is correspondingly improved. Therefore, palletizing machines are also very applicable in the production of industrial products. Moreover, because the palletizing machine is easy to operate and can replace workers' work, it greatly reduces the cost of human resources in industrial production and is favored by company bosses.

4. Food industry

The use of robots in the food industry is becoming increasingly widespread. Even in many traditional industrial fields, people are trying to have robots replace humans in work, just like in the food industry. At present, the developed food industry robots include packing robots.

The advantages of the robot palletizing machine are that it occupies a small area, can rotate 360 degrees, is more flexible to operate, has a stronger ability to grasp and palletizing, reaching 800-1200 bags per hour, and can handle the palletizing work of two production lines simultaneously. Its application industries are very extensive. For instance, bagged and boxed products can be used in flour mills, carton factories, beverage factories, breweries, feed mills, cement plants, etc., as well as in food and medicine industries. However, due to their high cost and price, they are not suitable for small and medium-sized enterprises with relatively small production capacity.

The advantages of the high-position palletizing machine are its stable structure, simple operation, extremely low failure rate and very low maintenance cost in the later stage. Its palletizing capacity is 400-600 bags per hour, fully meeting the material palletizing requirements of a production line for small and medium-sized enterprises. It is mainly applied in the palletizing of bagged enterprises in the flour industry, feed industry, fertilizer industry, cement industry, etc. The cost of high-position palletizing machines is much lower than that of robot palletizing machines, and they can meet the production requirements of small and medium-sized enterprises. Therefore, in the current domestic market, the usage of high-position palletizing machines is much higher than that of robot palletizing machines.

In what industries are palletizing machines mainly used? Based on the current market demand, the application of palletizing machines is becoming increasingly widespread. The demand for palletizing machines from enterprises will continue to rise. To meet the market demand, domestic intelligent equipment manufacturing enterprises must rise to the challenge and constantly enhance their independent research and development capabilities. Only in this way can they achieve better development!

Previous Article:The future development trend of intelligent robots

Next Article:The reasons why the palletizing machine cannot start normally