The main application scenarios of industrial robots

Release Date:2023.01.31 Page Views:46850Artificial intelligence is booming, and all kinds of robots keep emerging on the Internet and in the news. However, in the industrial field, the main application areas of industrial robots remain clear and well-defined. No matter how many robots there are in possession, most of them are currently distributed in these fields.

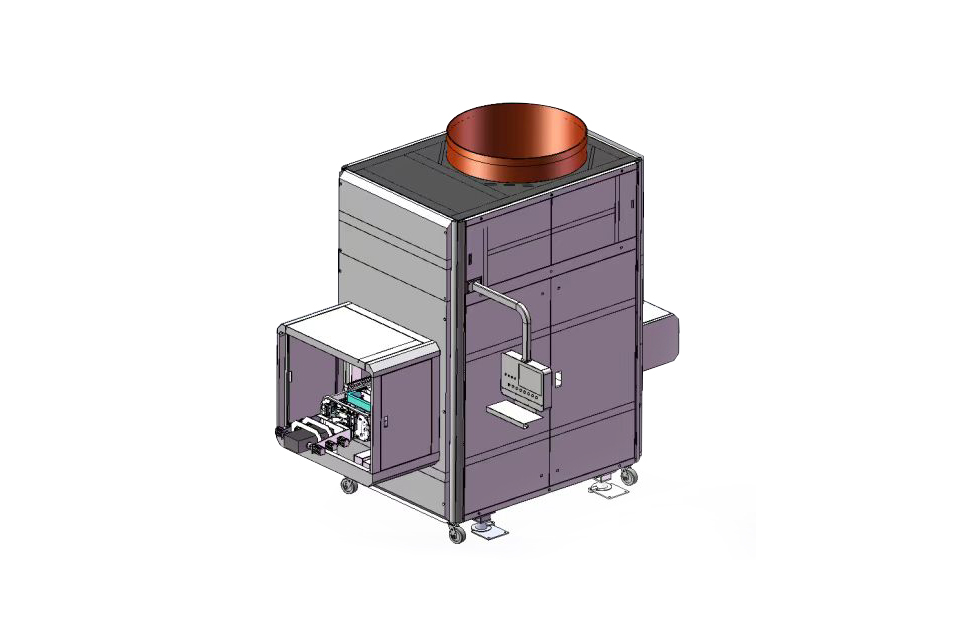

Fully automatic brick distribution and retrieval integrated machine (Single brick type)

01 Transmission line

Robot system: By having robots accurately and quickly assemble parts at specific workstations, the production line can achieve a high degree of automation. Robots can adjust to each other according to certain principles to meet the jumping requirements of process points. Provide a communication interface with the superior management system.

Automated robots and carrier logistics automation systems can be applied in industries such as building materials, home appliances, electronics, chemical fibers, automobiles, and food.

02 Adhesive coating

The robot gluing workstation is a robot application system developed by the Robot Center, mainly including robots, gluing systems, gluing workbenches, workstation control systems and other peripheral support equipment.

To enhance the reliability of the system, the robots of the glue workstation and the glue supply system generally adopt foreign products. According to the user's requirements, the workbench, control cabinet and peripheral support equipment were designed and manufactured, and the integration of the collage system was completed.

The workstation has a high degree of automation and is suitable for multi-variety and large-scale production. It can be widely applied in industries such as automotive windshields, automotive headlights and motorcycles, building materials and doors and Windows, and solar photovoltaic cell collage.

03 Welding

With the development of electronic technology, computer technology, numerical control technology and robot technology, the automatic arc welding workstation has become increasingly mature since it was put into production in the 1960s.

04 Automatic Assembly

The automatic packaging robot and palletizing workstation is an integrated system, which includes industrial robots, controllers, programmers, robot grippers, automatic disassembly/stacker cranes, pallet transportation equipment and positioning, pallet mode software, etc. It is also equipped with automatic weighing, labeling, inspection and communication systems, and is connected to the production control system to form a complete integrated packaging production line.

05 Automatic Welding

The automatic welding station for rotating shafts is used for welding various workpieces based on rotating shafts (with multiple cantilevers on them). It consists of a welding robot, a rotating two-station positioner (for multiple seasons) and a set of tools. On the same workstation, various types of automatic rotating shaft welding can be carried out using different anchors, and the relative positions of the welding are very high.

Due to the use of a dual-station positioner, the workpiece can be disassembled at other stations during welding, which greatly improves efficiency.

With the promotion of industrial robot policies and demands, industrial robots are bound to be applied in more industries in the future, gradually replacing most of the mechanical energy output of human labor.