A manufacturing method of an automatic fabric spreading machine

Release Date:2023.02.01 Page Views:47751The present invention provides an automatic concrete placing machine, aiming to achieve the purpose of continuous concrete placing, adjusting the amount of concrete placed according to different specifications of precast concrete components, and real-time observation of the remaining concrete amount in the hopper

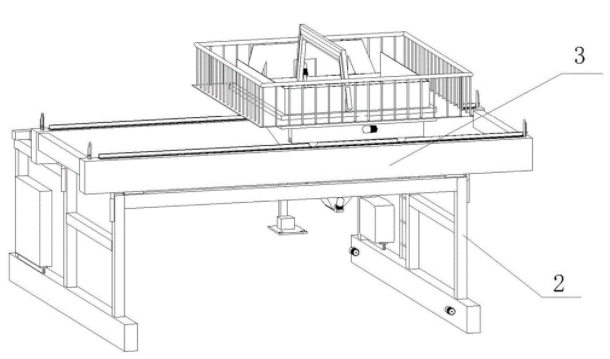

An automatic placing machine has two or more tracks that extend longitudinally and infinitely along the ground. Between the two tracks, prefabricated concrete molds are placed. The placing machine has a lower placing machine frame main body and an upper placing device. The placing device is connected to the placing machine frame main body through a guiding mechanism. The material spreading device is fixed above the main body of the material spreading machine frame through the guiding mechanism. The material spreading device can float up and down relative to the main body of the material spreading machine frame. A pressure sensor is provided between the material spreading device and the main body of the material spreading machine frame. Two pulleys are provided at the bottom of the main body of the material spreading machine frame, and the pulleys are slidably connected to the track.

The material distribution device has two main trusses and a hopper. The hopper is located between the two main trusses, and the main truss is perpendicular to the track. The hopper has a top feeding port, a middle hopper body and a bottom discharging port. The hopper body is slidably connected to the main truss through a second pulley. The material distribution machine is also equipped with an operation seat and a display screen. The display screen is fixed on the main body of the hopper. The operation seat is supported by a bracket and suspended in front of the display screen. The discharge port is equipped with a discharge baffle.

The guiding mechanism serves to connect and protect the placing device and the main body of the placing machine frame, ensuring that the placing device does not shift when moving up and down above the main body of the placing machine frame, and that it can float up and down straight above the main body of the placing machine frame without shaking left and right. The material distribution device is equipped with a hopper filled with concrete. The amount of concrete in the hopper is sensed by a pressure sensor. The pressure sensor transmits the sensed signal through pipelines to the display screen. Staff can read the data displayed on the screen to know the amount of concrete in the hopper. The material distribution device is equivalent to the load-bearing plate in the scale. The amount of concrete in the hopper can be accurately sensed by the pressure sensor and transmitted to the display screen for the staff to read. Moreover, the staff can control the opening and closing of the discharge baffle through the remote control. After the discharge baffle is opened, during the concrete discharge process, the pressure sensor senses the concrete discharge data in real time and transmits it to the display screen. During the concrete discharge process, the data on the display screen keeps jumping. As the amount of concrete changes, the data on the display screen changes in real time. The operator sits on the operation seat and controls the opening and closing of the discharge baffle by reading the data on the display screen, thereby controlling the concrete discharge volume.

Between the two tracks, there are multiple prefabricated concrete molds continuously arranged along the longitudinal direction of the tracks. The placing machine is slidably connected to the tracks through pulleys. The placing machine can move longitudinally along the tracks. It can move forward or backward on the tracks. As the placing machine moves forward along the tracks, it can continuously inject concrete into the molds. The convenient concrete placing machine can continuously place concrete into the arranged concrete molds, quickly and continuously moving from one concrete mold to the next without any pause. Moreover, the amount of material discharged is controllable, and the remaining concrete volume in the hopper and the amount of material discharged can both be displayed and read on the display screen. The hopper can slide laterally along the main truss, facilitating the lateral adjustment of the position of the discharge port relative to the concrete mold and facilitating the distribution of the hopper into the concrete mold in the lateral direction. Therefore, compared with the concrete mold, the placing machine can be adjusted in both the longitudinal and transverse directions, which can achieve the purpose of uniform distribution into the concrete mold.

In this structure where a pressure sensor is set between the placing device and the main frame of the placing machine, the hopper and the main truss are equivalent to weighing plates. The pressure sensor senses the amount of concrete in the hopper and transmits and displays the sensing signal on the display screen for the operator to read. Moreover, the operator can know the amount of concrete released each time during the operation of the placing machine.

The operator controls the opening and closing of the discharge baffle by operating the remote control. The pressure sensor transmits the sensed data to the display screen, and the data on the display screen is updated in real time. According to the different specifications of the precast concrete components to be made, the amount of concrete required also varies. By reading the data on the display screen, the amount of concrete released into the concrete mold can be known. Based on the remaining concrete volume in the hopper, the amount of concrete released each time can be known, and the amount of concrete released into the concrete mold each time can be controlled. The foot-operated switch can control the fabric spreading machine to move forward and backward along the track. It adopts a foot-operated button set at the seat position, which is more convenient to operate.

The above-mentioned automatic placing machine, further, the top of the frame body of the placing machine is provided with two secondary trusses, the main trusses are set above the secondary trusses, the main trusses are parallel to the secondary trusses, the main trusses are connected to the secondary trusses through the guiding mechanism, the two ends of the secondary trusses are welded with Angle steels, and the lower surface of the main trusses is welded with a second Angle steel. The second Angle steel is inserted into the Angle steel, and the Angle steel and the second Angle steel form a guiding mechanism. The guiding mechanism is composed of Angle steel and a second Angle steel. The second Angle steel is inserted into the Angle steel, and within the Angle steel, it can float up and down within the second Angle steel. Moreover, due to the adoption of this Angle steel structure, while supporting the main body of the placing device and the placing machine frame, the floating components of the pressure sensor are also protected, ensuring that the floating components can float up and down straight without deviation.

The pressure sensor and the guiding mechanism are four in total, respectively arranged at both ends of the secondary truss and the main truss. The pressure sensor is arranged between the secondary truss and the main truss, placed at both ends of the secondary truss and in contact with the main truss. Four pressure sensors and guiding mechanisms are set between the placing device and the main body of the placing machine frame, respectively placed at the four corners of the main body of the placing machine frame. They serve to support the placing device while, as the pressure sensors and guiding mechanisms are distributed around, they can measure the concrete contained in the placing device.

Previous Article:The working principle of the fabric spreading machine

Next Article:The main application scenarios of industrial robots