What are the commonly used grippers for palletizing robots?

Release Date:2023.02.11 Page Views:50523With the development of the social economy, the consumption of goods in our country is increasing. The growth in demand for packaging machinery has also led to the emergence of automatic packaging production lines in the market at a faster pace. With the growth in demand for automatic packaging production lines, domestic packaging machinery manufacturers have sprung up like mushrooms after rain. The robot wharf mainly relies on the mechanical hands on the equipment for palletizing, that is, the mechanical hands on the equipment make the palletizing robot superior to the palletizing machine. Compared with ordinary palletizing machines, palletizing robots have some unique advantages. Automatic palletizing machine

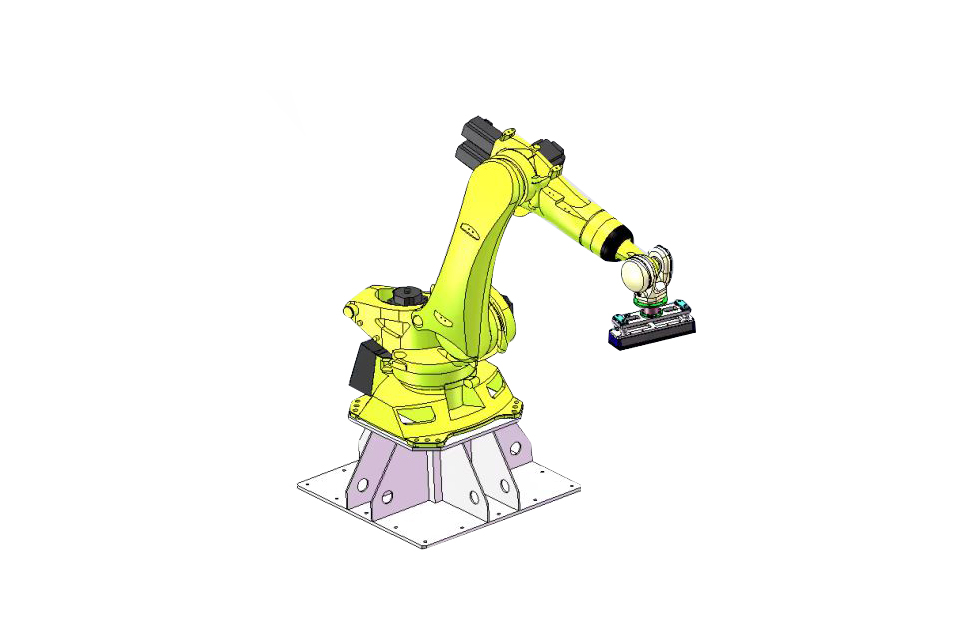

Fully automatic palletizing robot

The robot palletizing machine is an extension and expansion of the functions of workers' hands, feet and brains. It can replace people in working in harsh environments such as danger, toxicity, low temperature and high temperature. It can help people complete heavy, monotonous and repetitive work, improve labor productivity and ensure product quality.

As one of the important components of palletizing robots, the working performance of palletizing manipulators, including parameters such as reliability, simple and novel structure, and light weight, is of great significance to the overall working performance of palletizing robots. Palletizing machines can be designed with different types of mechanical starting points according to different products. Palletizing robots have the advantages of high efficiency, high quality, wide application range and low cost, and can complete palletizing work very well.

The commonly used grippers for palletizing robots mainly include:

This mechanical gripper is mainly used for high-speed packaging bags, especially for flour. Packaging bags for feed, cement, chemical fertilizers, etc.

2. It is mainly applicable to palletizing boxes. Clamping is mainly used for packaging full cases or ordinary cases and can be applied in various industries. One or more (boxes) can be encoded at a time.

3. Clamping is mainly used for the suction force of suction cups, such as laminated packaging boxes. Beer box. Plastic box. Cartons, etc.

4. It is suitable for collaborative crawling on multiple workstations. It is a flexible combination of the first three grippers and can simultaneously meet the code requirements of multiple workstations.

5. It is used to detect metal foreign substances mixed in the production process, such as in food, medicine, cosmetics, textiles, etc.

6. Through weight inspection, the quantity of finished products, losses and incorrect loading amounts can also be determined, and qualified products can be calculated respectively. Overweight products and overweight products, in order to achieve the purpose of product quality control.

7. The utility model is used to complete the process of abnormal metal content in packaging bags and repeatedly check the weight error of the packaging bags during weighing. The automatic eliminator can also be integrated into metal detectors or weight measuring machines.

8. According to the prearranged grouping procedure, the material bags are conveyed from the conveyor. Pour and rotate, and then transfer to the next process.

9. After the bags pass through the conveyor line, they must be compacted into shape by rollers and conveyed to the waiting roller conveyor to evenly disperse the possible accumulated materials inside the bags.

10. Facilitate the turning during the material conveying process and the connection with the next process.

The above are the commonly used types of grippers for palletizing robots. The gripper of the palletizing robot is an important component of the palletizing robot. Choosing a good palletizing robot gripper can improve the efficiency of the palletizing machine.