What types of vacuum packaging machines for rice are there?

Release Date:2023.02.13 Page Views:49840Rice is one of our main foods. It has the effects of tonifying qi, strengthening the spleen and nourishing the stomach. Rice is sold in supermarkets and supermarkets. Generally, there are two common forms: vacuum-packed and loose packaged. Vacuum-packed rice can extend its shelf life and has a more elegant and generous outer packaging, making it an excellent gift choice for people. So, what types of true vacuum packaging machines for rice are there? Let's take stock together today. Rice bagging machine

1. Double-chamber vacuum packaging machine for rice Vacuum packaging machines. The double-chamber vacuum packaging machine is a widely used vacuum packaging machine. It has two vacuum chambers. When one vacuum chamber is being evacuated, the other can be used to place products. This also saves the time spent waiting for vacuuming, thereby enhancing work productivity. This kind of vacuum packaging machine is also widely used to package rice. Some rice manufacturers will package the rice into the shape of rice bricks. Before packaging, just put the packaging bag into the mold shaped like a rice brick, then put the rice into the bag, and place it in the vacuum chamber of the double-chamber vacuum packaging machine for vacuuming. In this way, the shape of the packaged rice will become like a rice brick. Thus, the packaging effect of rice bricks was achieved.

Ii. Rice Vacuum Packaging Machine - Rolling Vacuum Packaging Machine. The rolling vacuum packaging machine is a vacuum packaging machine that continuously outputs products. The obvious difference between this vacuum packaging machine and the double-chamber vacuum packaging machine is that after the product is vacuumed, the upper cover of the rolling vacuum packaging machine moves up and down back and forth. The common sealing line lengths of the rolling vacuum packaging machine are generally 1000mm, 1100mm, and 1200mm, so that multiple bags of products can be placed at one time. After the vacuum packaging of the products is completed, the equipment will output the products to the back of the equipment through the conveyor belt. Only the material basket for receiving the products needs to be placed on the back of the equipment.

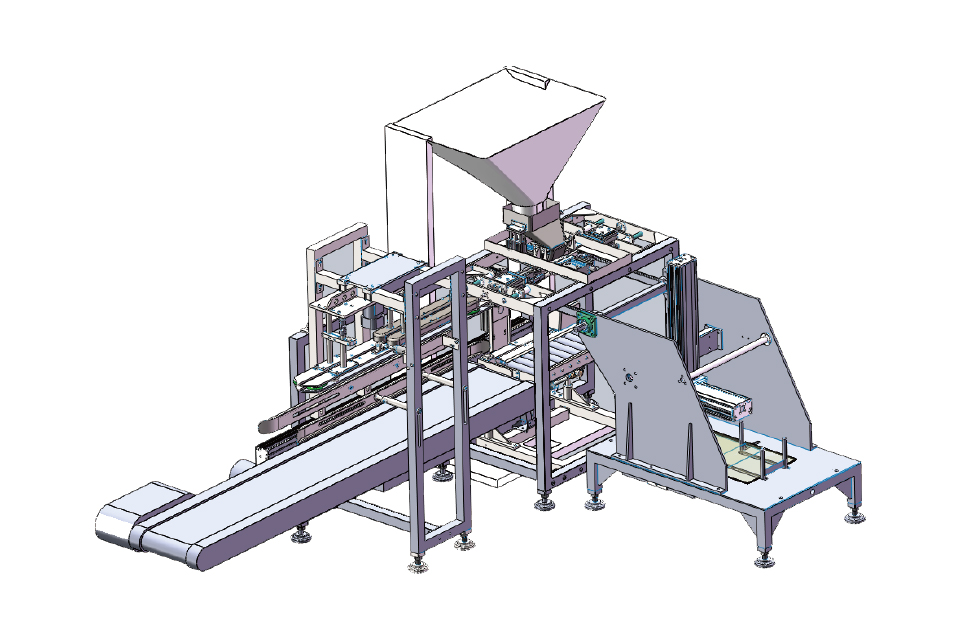

Iii. Fully automatic bag-feeding Vacuum Packaging Machine for Rice Vacuum Packaging Machines. This equipment is a fully automated vacuum packaging machine. It can achieve automatic bag feeding, automatic weighing, automatic material feeding and automatic vacuuming. The entire operation process is automatically controlled by the system. The entire packaging process can be controlled on the entire operation panel. As long as the parameters required for each operation link are set, the equipment can achieve automated production according to the set program. In this way, one device can realize the operation of a production line. It not only improves work productivity but also saves labor costs.

From the introduction of the above three major types of equipment, it can be seen that the rice vacuum packaging machine can be packaged by different types of equipment. The specific choice of which type of vacuum packaging machine to use also depends on the desired packaging effect and the daily working capacity. After considering these two aspects, it is still necessary to have multi-faceted communication with the rice vacuum packaging machine manufacturer. Since each factory has different demands for products, it is still recommended to go to the factory in person, bring your own rice products and do the actual packaging. Only in this way can you see the packaging effect more intuitively, and also purchase a rice vacuum packaging machine that suits you.