The relationship between Fully automatic palletizing machines and manufacturing

Release Date:2023.02.14 Page Views:50645In recent years, with the transformation of people's consumption concepts, the beverage industry has witnessed a peak of growth and reached an unprecedented height. However, with the growth and development of enterprises and the expansion of production scale, coupled with the increase in costs such as raw materials, production and logistics, enterprises are also facing the problem of how to control costs.

In fact, the main cost of these enterprises still lies in production costs. Especially in recent years, with the continuous increase in labor costs, enterprises have become somewhat overwhelmed. Therefore, automated equipment has become a new option for enterprises. Among them, the fully automatic palletizing machine is a representative example.

Due to the increase in labor costs, especially in the palletizing process, enterprises need to use a large number of manual workers in production. However, manual operations not only have a large amount of labor, slow efficiency, and heavy workloads, but also the final results are not ideal. Or even if a work-related injury occurs, not only will the workers' health be harmed, but the enterprise's costs will also increase accordingly.

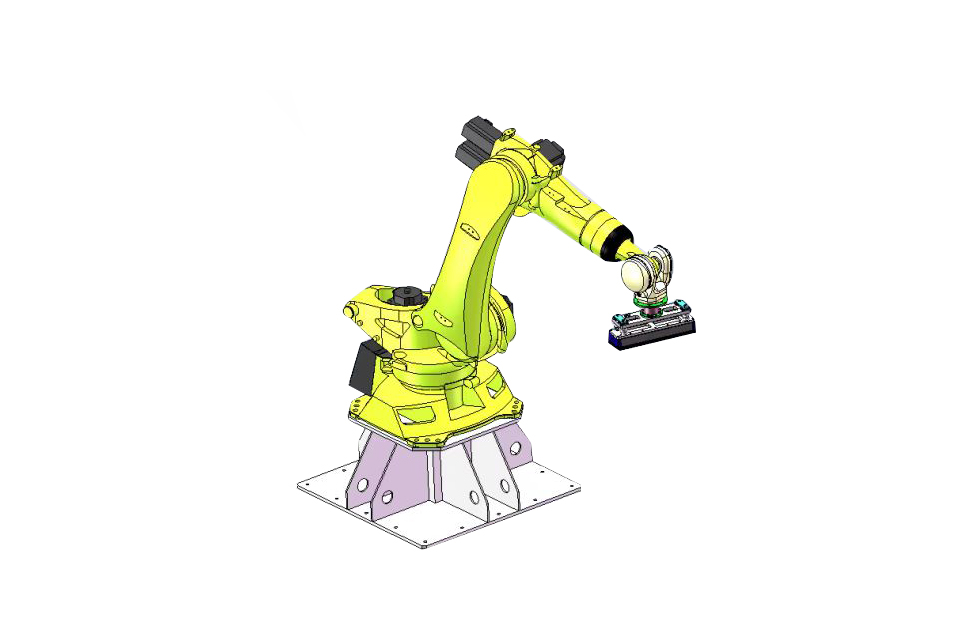

If fully automatic palletizing machines are used for palletizing, not only can this part of labor costs be saved, but also they are highly efficient, fast and precise in palletizing. Therefore, at present, some domestic enterprises that use bagged packaging for feed, fertilizer, flour, cement, etc. choose to use fully automatic palletizing machines to replace manual labor to complete the palletizing process.

From the perspective of industrial chain development, the demand from downstream industries is bound to drive the development of upstream industries. According to the current development trend of the domestic beverage industry, the market demand for fully automatic palletizing machines is still very considerable. According to market research, the use of fully automatic palletizing machines can increase the annual output value of these enterprises by up to 100 million yuan. It can also be said that the two are mutually beneficial and develop in tandem.

It can be seen from this that the use of automated palletizing machines has largely reduced production costs and increased benefits for enterprises. Conversely, the choice of enterprises has also driven the development of automated equipment.