What significance does the automatic weighing and placing machine have for the forming of refractory bricks

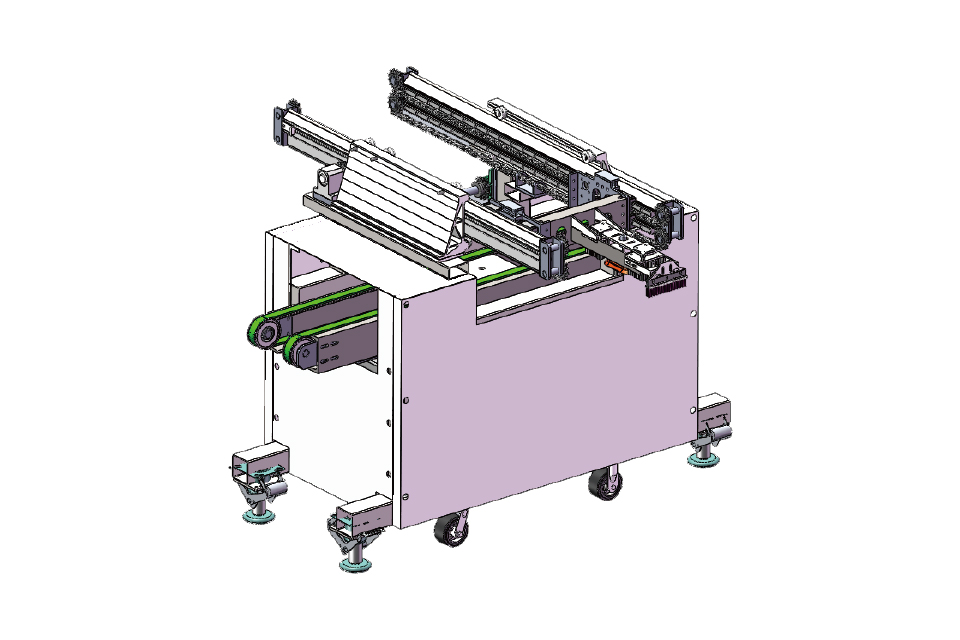

Release Date:2023.02.22 Page Views:46658With the continuous improvement of the government's requirements for the refractory materials industry and the constant calls and evaluations for green refractory materials and green factories, more and more refractory materials enterprises have begun to respond to the call for automation. As for the current situation of refractory material enterprises, there are still many refractory material enterprises whose production is completed through a large amount of manual operations. The automatic weighing and spreading machine has advantages such as intelligent operation, weighing calibration, single weight adjustment of brick type, intelligent protection, output report export, whole machine movement, and leftover material clearance. These features have strengthened enterprise management and reduced production costs. So, what significance does the automatic weighing and spreading machine have for the forming of refractory bricks? Automatic placing machine

Realize automation and reduce labor intensity. The automatic weighing and spreading machine automatically spreads, weighs and feeds materials according to the parameters set by the user. The entire process is automatically completed without human intervention, making the precision of the product controllable and ensuring the consistency of the refractory bricks after forming. At the same time, it reduces the labor cost expenditure for enterprises, changes the situation where enterprises need a large amount of manual assistance to complete work, and lowers the labor intensity.

Lay the foundation for full-line automation. The automatic weighing and spreading machine plays a bridging role in the powder forming production line. It can be connected to the mixer at the top and seamlessly integrated with the servo electric screw press at the bottom, laying the foundation for the full automation of the powder forming production line. Meanwhile, the automatic weighing and spreading machine can collect and statistically analyze production data, automatically generate daily reports on the unit weight, daily output, monthly output and annual output of various brick types, providing data support for the improvement of refractory brick forming processes, thereby enhancing production efficiency.

The automatic weighing and spreading machine makes the material accuracy in the spreading process change from uncontrollable to controllable, ensuring the size and weight of the products. The emergence of automatic placing machines has laid a solid foundation for the full automation of powder forming production lines. It is also a response to the government's call and a solution to the problems of refractory material enterprises.

Previous Article:A Comprehensive guide to the Basics of Industrial robots

Next Article:Key features of weighing and packaging machines