A Comprehensive guide to the Basics of Industrial robots

Release Date:2023.02.23 Page Views:455061. Subject

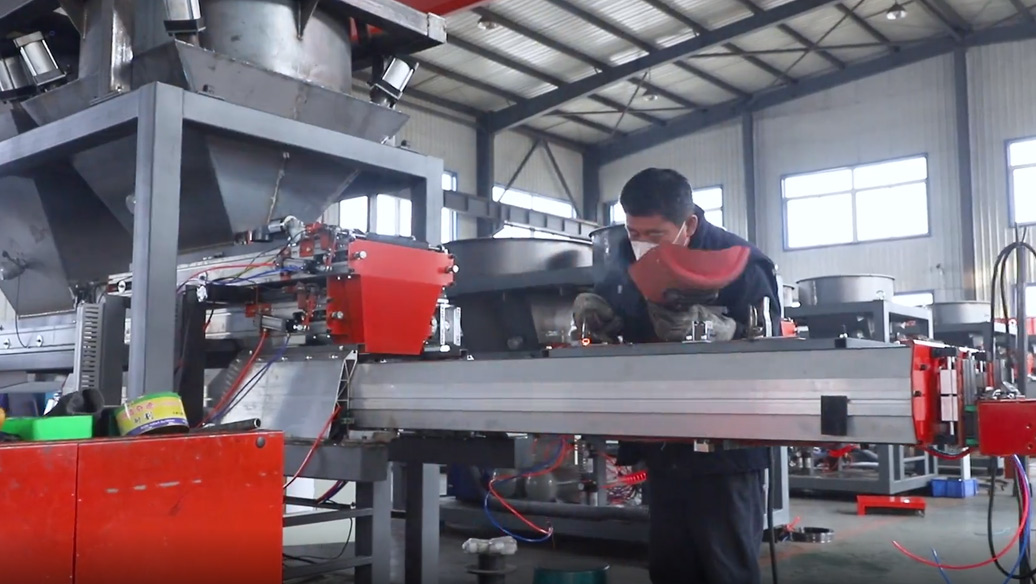

The main machinery, namely the base and the actuator, includes the upper arm, lower arm, wrist and hand, forming a multi-degree-of-freedom mechanical system. Industrial robots have six degrees of freedom or more, and their wrists usually have one to three degrees of freedom for movement.

2. Drive system

The drive systems of industrial robots are classified into three major categories based on their power sources: hydraulic, pneumatic and electric. According to the requirements, these three examples can also be combined and integrated into a composite drive system. Or it can be driven indirectly through mechanical transmission mechanisms such as synchronous belts, gear trains, and gears. The drive system consists of a power unit and a transmission mechanism, which are used to actuate the mechanism to perform corresponding actions. Each of these three fundamental drive systems has its own characteristics. Currently, the mainstream one is the electric drive system.

3. Control System

The robot control system is the brain of the robot and the main element that determines the robot's functions and capabilities. The control system retrieves instruction signals from the drive system and actuator according to the input program and conducts control. The main task of industrial robot control technology is to control the movement range, posture and trajectory, and action time of industrial robots in the working space. It features simple programming, software menu operation, friendly human-computer interaction interface, online operation prompts and convenient application.

4. Perception System

It is composed of an internal sensor module and an external sensor module, obtaining meaningful information from the internal and external environmental states.

Internal sensors: Sensors used to detect the robot's own state (such as the Angle between the arms), mostly for detecting position and Angle. Specifically, there are: position sensors, Angle sensors, etc.

External sensors: Sensors used to detect the environment where the robot is located (such as detecting objects, the distance from objects) and the condition (such as detecting whether the grasped object has slipped). Specifically, there are distance sensors, visual sensors, force sensors, etc.

The application of intelligent sensing systems has raised the standards of mobility, practicality and intelligence of robots. Human perception systems are as dexterous as robots in dealing with external world information. However, for some special information, sensors are more effective than human systems.

5. End effector

The end effector is a component connected to a joint of the manipulator. It is generally used to grasp objects, connect with other mechanisms and perform the required tasks. In the manufacturing of industrial robots, end effectors are generally not designed or sold. In most cases, they only provide a simple gripper. Usually, the end effector is installed on the flange of the robot's six axes to complete tasks in a given environment, such as welding, painting, gluing, and parts loading and unloading, which are tasks that need to be accomplished by industrial robots.