Palletizing robots have become a common phenomenon in factories to replace human labor

Release Date:2023.02.27 Page Views:46201Nowadays, in many factories, one can see all the equipment in the entire workshop running non-stop. The higher the level of automation, the fewer the labor force. The scene where many people worked together to handle positions in the past no longer exists. Why have palletizing robots replaced manual handling and become a common phenomenon?

Palletizing robots can undertake many dangerous or monotonous palletizing and handling tasks, and many occupational diseases, work-related injuries and high costs that need to be paid can be avoided.

Secondly, the working mode of palletizing robots is fixed, so the product quality is stable and it will also bring certain profits to enterprises. Moreover, robots can work 24 hours a day, the productivity of products can be budgeted, and inventory can be well controlled. Cost savings in each item of the total product value will enhance the competitiveness of the product in various markets.

3. Robots can be used in small-batch production and have high flexibility.

In the past two years, against the backdrop of the gradual disappearance of China's advantage of cheap labor and the significant increase in labor costs, factors such as "labor shortage" and "high costs" have intertwined and superimposed in the construction machinery industry, squeezing the profit margins of manufacturing enterprises and highlighting the current survival predicament of small and medium-sized enterprises in the industry. At the same time, it will prompt potential and capable enterprises to seek new ways out amid the pain of transformation and upgrading, and the market will be reshuffled. China's construction machinery industry is confronted with huge challenges of transforming to a higher level, undertaking advanced manufacturing at the international level, and participating in international division of labor. "Replacing humans with machines" is an inevitable trend.

5. The aging of society is becoming increasingly prominent, and humans need palletizing robots as assistance and supplements. Furthermore, with the improvement of the national education level, the labor force at the grassroots level is increasingly scarce. More robots will be involved in industrial manufacturing, material transportation and even space exploration.

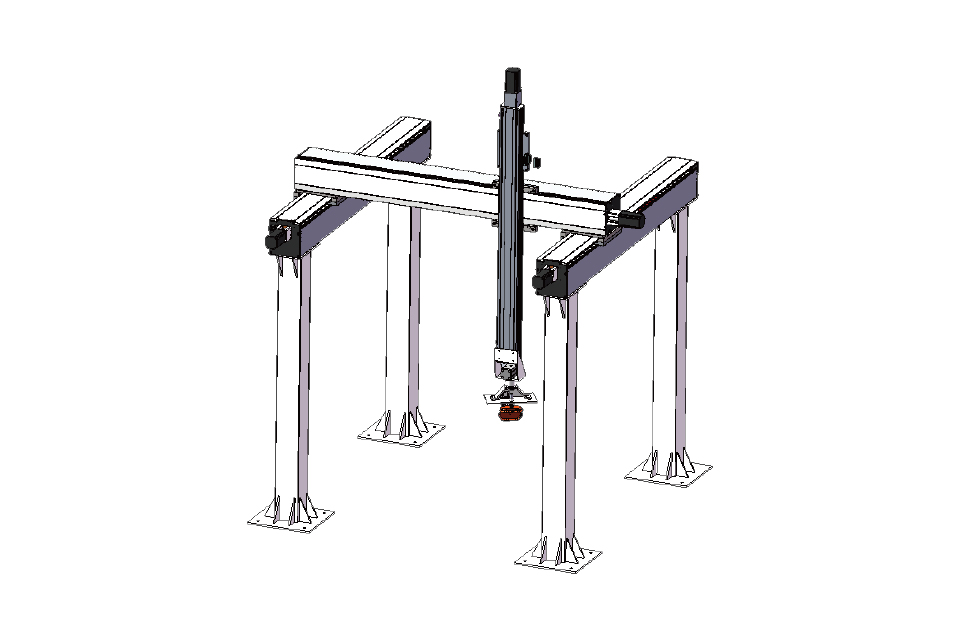

The complete set of equipment for industrial automated production lines of palletizing robots has become the mainstream and future development direction of automated packaging and palletizing equipment. Automated production lines that employ a large number of industrial robots can enhance product quality, improve production efficiency, and prevent a significant number of industrial accidents.

Previous Article:Maintenance and repair of the fabric spreading machine

Next Article:What should be noted when maintaining a robot?