What are the differences between palletizing robots and high-position palletizing machines

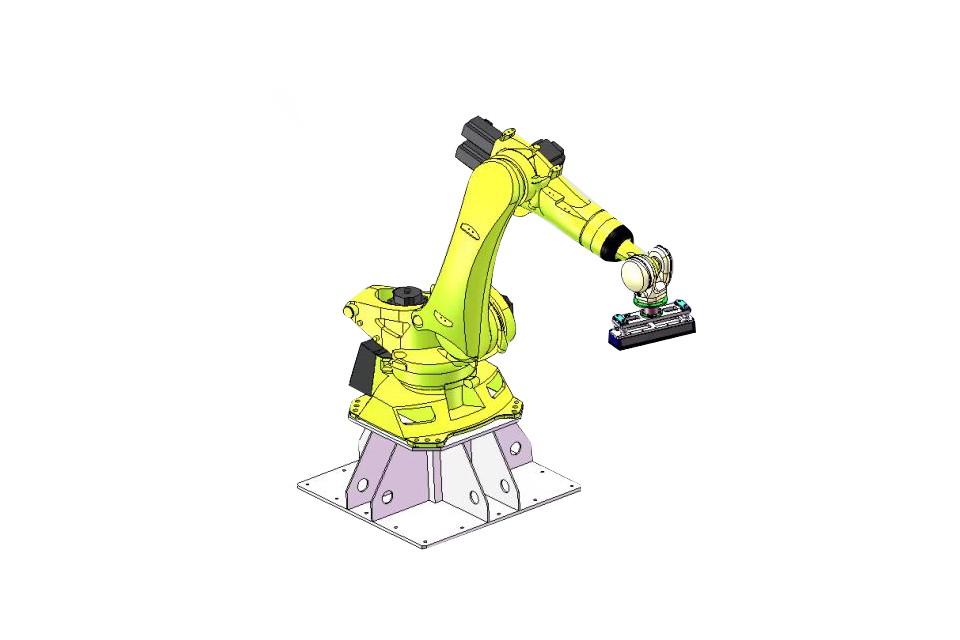

Release Date:2023.03.11 Page Views:48849Granular material packaging requires the use of palletizing machines for packaging. Palletizing machines can be classified into palletizing robots and high-position palletizing machines based on the degree of automation. Currently, the usage rate of palletizing machines in the market is gradually increasing. According to the development prospects of the industry, palletizing machines will also be one of the mainstream products in the future market and a key product that major packaging automation manufacturers are increasing their research and development and production of.

Both high-position palletizing machines and palletizing robots are automatic packaging machines and are relatively advanced modern production and packaging equipment. Both have advanced packaging techniques, but there are only many minor differences. In terms of the degree of automation, the difference between high-position robots and palletizing robots is that one is slower while the other is faster. In comparison, the production efficiency of high-position palletizing machines may be slightly lower, while that of fully automatic ones should be significantly higher. Therefore, the specific choice between palletizing robots and high-position palletizing machines should still be determined based on our own production requirements. If the budget is not high and the output is small, it is recommended to choose the high-position palletizing machine model. When our output is large and the production requirements are high, palletizing robots can be chosen.

Therefore, when choosing equipment, what we need to consider is which type of packaging equipment is suitable for our packaging products, and select the appropriate model in combination with production requirements and budget conditions.

Previous Article:What are the features of popular palletizing machines?

Next Article:The automatic weighing and packaging machine measures food