The packaging types and wide applications of palletizing robots

Release Date:2024.10.21 Page Views:61398When in use, palletizing robots are an organic combination of machinery and computer programs, providing higher production efficiency to a certain extent for modern production. Palletizing robots are used in the palletizing industry. Let's know its packaging type and application. Automatic palletizing machine

The packaging types, factory environments and customer demands of palletizing robots have turned palletizing into a tough nut to crack for packaging factories. To overcome difficulties, all aspects of palletizing equipment are being developed and improved, including the mechanical arms and the software for operating them. The market's demand for flexibility is increasing, and this trend has affected many aspects of packaging, including the back-end of the production line. Influential supermarkets like Walmart often need to customize random pallets, but each pallet needs to be customized, and the form of the pallet is occasionally repeated.

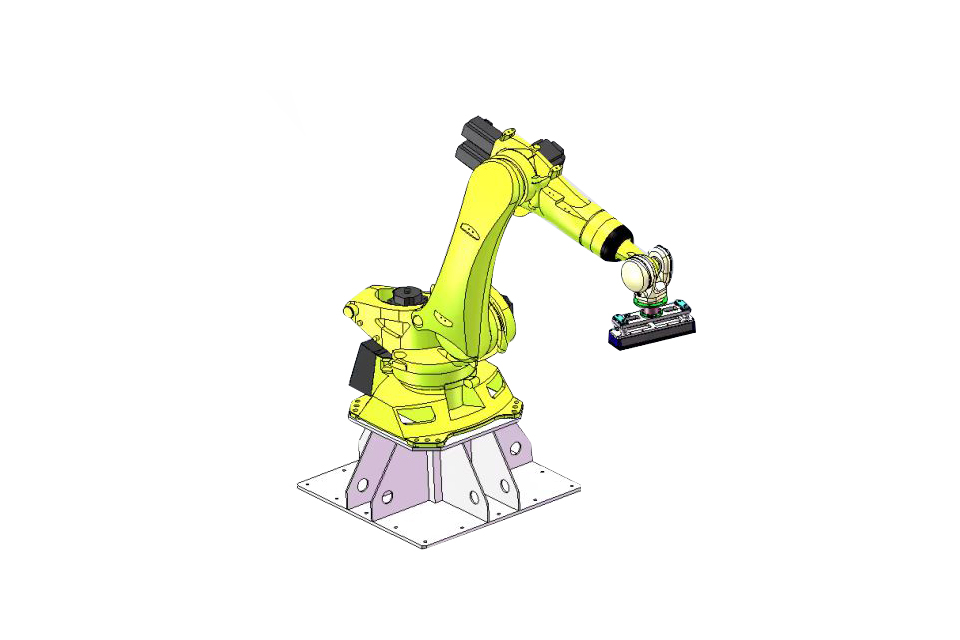

The palletizing robot adopts a patented coordinate robot, with flexible and compact installation space. The idea of building an energy-saving fully automatic block forming machine production line on a small scale has become a reality. With the continuous development of the economy and the rapid advancement of science and technology, robots have been widely applied in industries such as stacking, gluing, spot welding, arc welding, spraying, handling, and measurement.

The packaging types and applications of palletizing robots: Palletizing robots greatly save human space. The palletizing robot is flexible, accurate, stable and fast.