The automatic palletizing machine is a modern logistics equipment

Release Date:2024.11.29 Page Views:60295The automatic palletizing machine is a modern logistics equipment

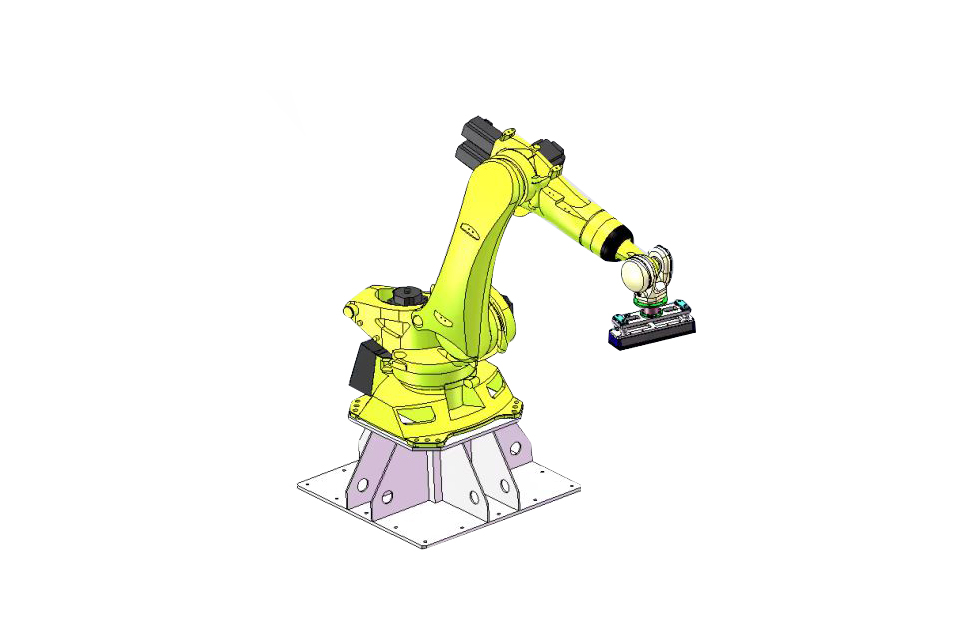

It is generally composed of main parts such as mechanical arms, conveyor belts, palletizing platforms, grasping devices and control systems. The mechanical arm is controlled to move through devices such as servo motors and can achieve multi-axis operation. The grasping device can be equipped with suction cups, fixtures, etc. according to the characteristics of the goods. The control system employs advanced control algorithms to schedule each component.

Working principle

The goods are conveyed to the working area by the conveyor belt. The positioning system uses sensors and other devices to precisely identify and locate the goods. Under the command of the control system, the palletizing device grabs the goods according to the preset rules and stacks them. This cycle of operation continues until the entire batch of goods is palletized.

Characteristics and advantages

1. High efficiency: It can work continuously for 24 hours, completing hundreds or even thousands of grasping and placing actions per hour, significantly improving palletizing efficiency and meeting the logistics demands of large-scale production.

2. Accuracy: Equipped with high-precision sensors and advanced control systems, it can place goods, ensuring neat and stable palletizing with tight and orderly stack shapes.

3. Strong adaptability: It can adapt to various types, sizes and packaging forms of goods. By adjusting parameters and grasping tools, it can handle objects of different shapes such as cartons, bagged items and canned products.

4. Save labor costs: It can replace a large amount of manual labor, reduce human input, lower costs, and also prevent manual operation safety accidents, enhancing workplace safety.

Application field

It is widely applied in the production and warehousing processes of industries such as food and beverage, chemical engineering, medicine, electronics, automobiles, logistics, and building materials. It can efficiently and accurately stack various products, enhancing production efficiency, product quality, and logistics operation efficiency.

全自动码垛机器人

Previous Article:Six features of palletizing machines

Next Article:The packaging types and wide applications of palletizing robots