Six features of palletizing machines

Release Date:2024.12.25 Page Views:60959The automatic palletizing machine is a modern logistics equipment

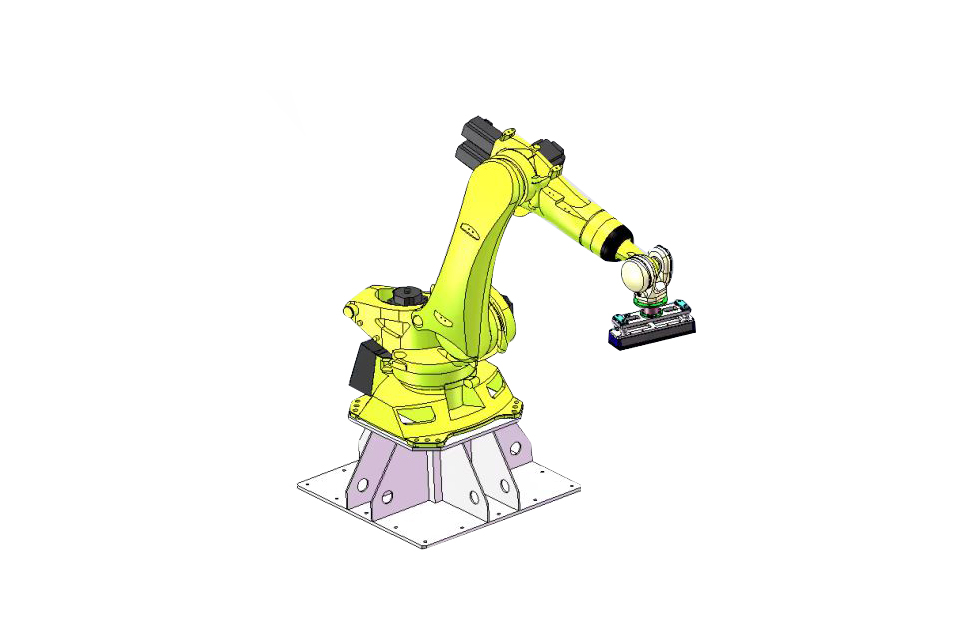

It is generally composed of main parts such as mechanical arms, conveyor belts, palletizing platforms, grasping devices and control systems. The mechanical arm is controlled to move through devices such as servo motors and can achieve multi-axis operation. The grasping device can be equipped with suction cups, fixtures, etc. according to the characteristics of the goods. The control system employs advanced control algorithms to schedule each component.

1. Simple structure and few components. Therefore, the failure rate of the components is low, their performance is reliable, maintenance and repair are simple, and the required inventory of components is small.

2. It occupies less space. It is conducive to the layout of production lines in the customer's factory building and can leave a larger warehouse area. Palletizing robots can be set up in narrow Spaces and be effectively used.

3. Strong applicability. When the size, volume, shape of the customer's products and the external dimensions of the pallets change, only minor modifications are needed on the touch screen, which will not affect the customer's normal production. However, it is quite troublesome or even impossible to modify mechanical palletizing machines.

4. Low energy consumption. The power of a typical mechanical palletizing machine is around 26KW, while that of a palletizing robot is approximately 5KW. It has greatly reduced the operating costs of customers.

5. All controls can be operated on the control cabinet screen, and the operation is very simple.

6. Just locate the starting point and the placement point, and the teaching method is simple and easy to understand.

全自动码垛机器人

Previous Article:Debugging methods for weighing and packaging machines

Next Article:The automatic palletizing machine is a modern logistics equipment